FEA Consultant Services

As an FEA consultant, PEC applies a variety of state-of-the-art tools from industry-leading solution providers to drive informed decision-making early in the digital phase of projects, reducing risk and potentially eliminating physical prototypes prior to production. We are well-versed in applying our tools and knowledge to first-of-a-kind projects.

Digital analysis techniques give PEC and its customers the ability to examine responses at a level of detail and to make multiple rapid iterations that would not be possible (or would be prohibitively expensive) in the physical world. These techniques can be applied not only to new development but to existing designs as well as post-incident investigations.

What is FEA Consulting?

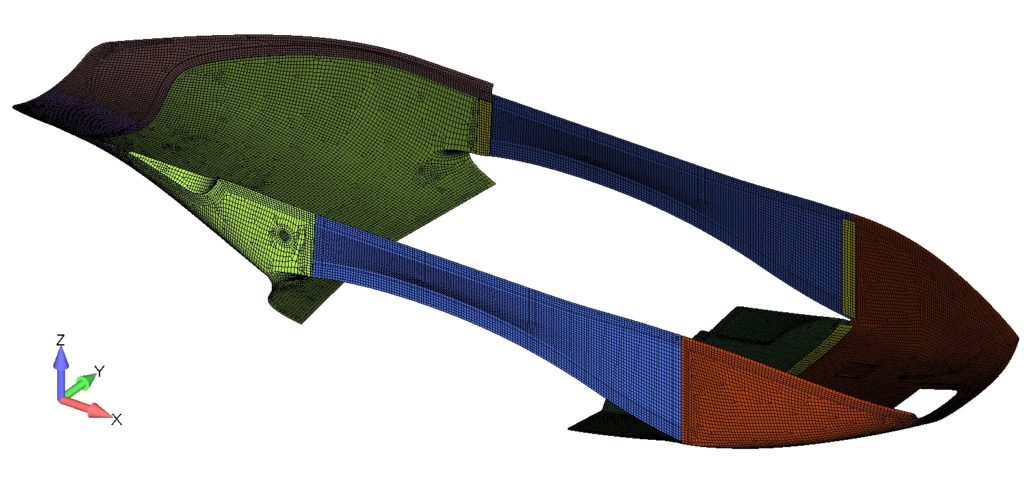

Finite element analysis (FEA) and finite element modeling (FEM) use the power of modern computers to subdivide complex parts and assemblies into simpler building blocks (elements) that can be readily analyzed. Basic physical equations are applied to each element to derive its response to its environment. Compute power is then tapped to track and reassemble the individual responses into results for the assembly as a whole. Modern graphical methods and processing are used at the beginning (pre-processing) to define the problem and at the end (post-processing) to collect, interpret, and display the results. This method is not unique or limited to any one industry but can be widely applied across many different areas.

PEC is Your Expert FEA Consultant

Today’s digital tools are very powerful, and a wide range of physical phenomena can be addressed (for example, stress, vibration, heat transfer, fluid flow, etc.). Nonetheless, not all phenomena should be included in every project. In addition to this, the most comprehensive tools are not push-button solutions but benefit from expert guidance, application, and interpretation. PEC’s expertise in understanding the intricacies of the tools, how and when to apply them, and how best to interpret and make sense of the results benefits every customer, whether or not they themselves are familiar with the process.

While today’s compute power may be virtually unlimited, project budgets and schedules most definitely are not. PEC’s familiarity with our tools allows for an efficient application of this critical capability within project constraints.

In the end, however, our work comes down to communication with the client. PEC’s deep knowledge and experience with these tools benefit the customer by providing actionable information. We do not simply push a button and generate stacks of colored images left for the customer to decipher. Analysis and communication are what we do and we ensure that customers know why we take a certain approach and what the results mean for them and their project.

Industries and Applications

Our services are useful for system development and analysis of many applications, including but not limited to:

- Aerospace: Structural analysis of metallic and composite structures. Inclusion of static, shock, vibration, and thermal effects from single components to complex assemblies.

- Transportation: Analysis of trailers, containers, and other specialty transport units, whether in serial production or as one-off designs.

- Industrial and manufacturing equipment: Comprehensive analysis of industrial components and other structures that can experience rapid loading, high pressure, extreme temperatures, or other effects. Includes the development of unique below-the-hook lifting devices.

- Damage prediction: Analysis and prediction of potential damage to transportation equipment subject to expected or unexpected loads.

- Mechanical engineering: Assist in resolving complex mechanical engineering problems.

Professional Services by Preissner Engineering & Consulting

We offer a wide range of solutions to help our customers streamline design and production processes in high-tech industries. As Professional Engineers, we take our charge to be responsible to our customers and society seriously. For more information on our services, contact us today.

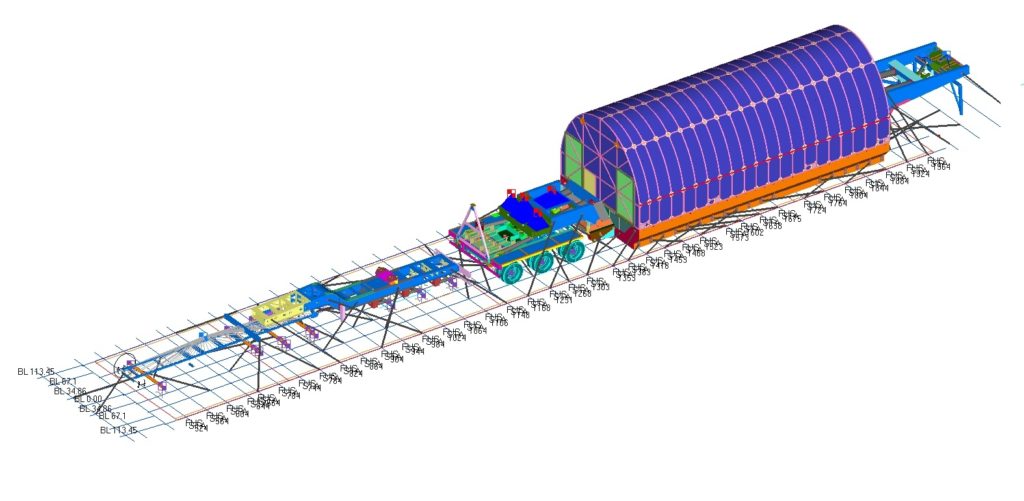

James Webb Space Telescope Transporter

James Webb Space Telescope Transporter